|

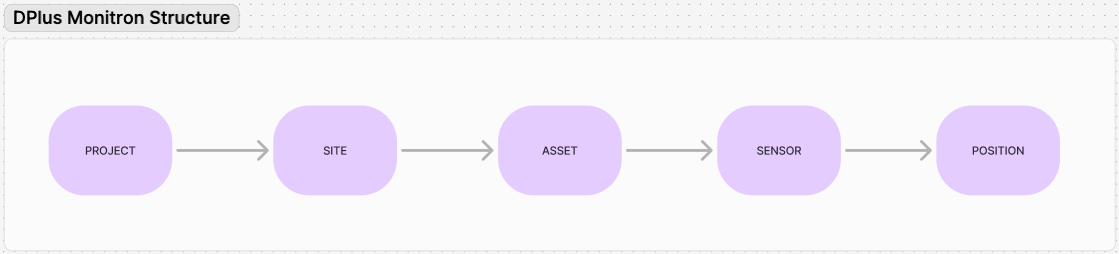

Project

|

Project is the highest-level organizational unit in the Monitron platform used to manage equipment monitoring and maintenance tasks. A Project represents an overall monitoring and maintenance operation, typically used to manage an entire plant, production line, or large equipment system.

|

- A Project can contain multiple sub-modules such as Sites, Gateways, Assets, and Sensors.

- Projects cannot be shared.

- Projects can only be created by a super admin.

|

Super admin

|

|

Site

|

Site is a collection of assets, gateways, and sensors that share a common goal.

|

- If you have a large number of assets, gateways, and sensors, Sites can help you manage these organizations more effectively.

- A maximum of 50 Sites can be created within a Project, with up to 100 assets and 200 gateways per Site.

|

admin

|

|

Getway

|

Gateway is a device used for data collection and transmission, responsible for uploading data collected from sensors to the cloud, ensuring real-time and complete data.

|

- Connection and pairing must be completed via the mobile app.

|

admin

|

|

Asset

|

Asset is the physical entity in the platform that represents the equipment or machines being monitored. It stands for the actual physical equipment that requires monitoring and maintenance, such as motors, pumps, compressors, etc.

|

- The foundation for viewing the health of equipment.

- Sensors are paired with assets and their components.

- Sensors can be placed in up to 20 locations on a single asset.

- Configuration can be done through the mobile or web application.

|

admin

|

|

Sensor

|

Sensor is the device used to collect data on the operating conditions of equipment, responsible for monitoring parameters like vibration, temperature, and humidity.

|

- The Sensor transmits data wirelessly to the Gateway, supporting real-time monitoring.

- Each Sensor corresponds to a specific measurement location, and the data can be used for equipment condition analysis and fault prediction.

|

admin

|

|

Position

|

Position in the platform refers to the installation location of a Sensor on an Asset, specifying the monitoring point of the sensor to ensure the accuracy of data collection.

|

- The Position defines where the sensor is installed on the equipment, such as on key parts like bearings or motors.

- The model defines positions for six types of assets, providing professional position suggestions and installation guidance.

- Users can customize multiple positions to achieve comprehensive equipment monitoring.

- Position information helps pinpoint and analyze equipment issues, offering more precise maintenance guidance.

|

admin

|